UPDATE- MARCH 2021

Unfortunately, the Eddy is not available for sale at this time. While it is my intention to develop this project further sometime in the future, it was originally designed as my capstone project in Industrial design at the University of new South Wales and was not fully refined to be brought to market.

Thank you to those who have reached out and inquired for updates, it's inspiring to see so many people passionate about our oceans.

Microplastic pollution is a serious threat to the health of our oceans. There are estimated to be 1.4 million trillion plastic fibres from synthetic clothing such as polyester and acrylic blends floating around in the marine environment. These tiny microplastic filaments referred to as microfibres are breaking free from our garments during washing. A single 6kg load of washing is estimated to flush 700,000 microfibres down the drain where they eventually find their way into the ocean, marine life and us. The Eddy prevents this with a filter to capture fibres from washing machine greywater, preventing them from polluting the environment.

The Eddy is a retrofittable washing machine filter designed to curb the amount of microplastic pollution released into the marine environment. It is more reliable, completely retrofittable, easier to clean, and more aesthetically considered than current offerings in the market.

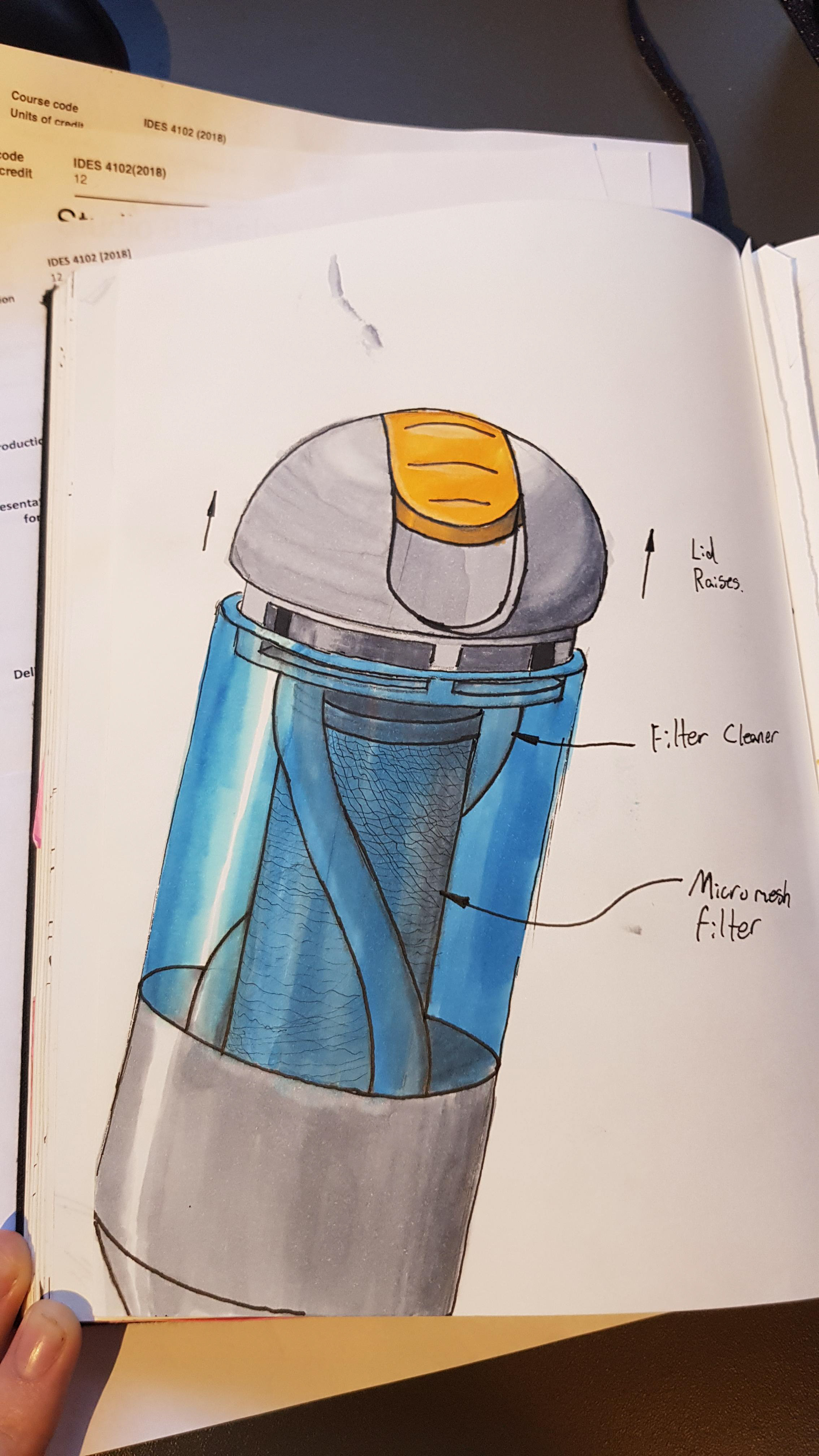

To capture microfibres, the Eddy features a stainless-steel micro-mesh filter. Contaminated water passes out of the washing machine and through the Eddy. Here these microfibres are separated from the water by this filter and the uncontaminated water passes on down the drain.

Over time the captured microfibres will begin to build up on the surface of the mesh, and so washing machine filters like the Eddy need regular maintenance to clean it. Where most filters require the filter to be removed from the device, the Eddy features an innovative cleaning system that allows fibres to be removed using a regular home vacuum cleaner.

The Eddy was the culmination of a year's work.

Some of my thinking, sketches and process can be seen below.

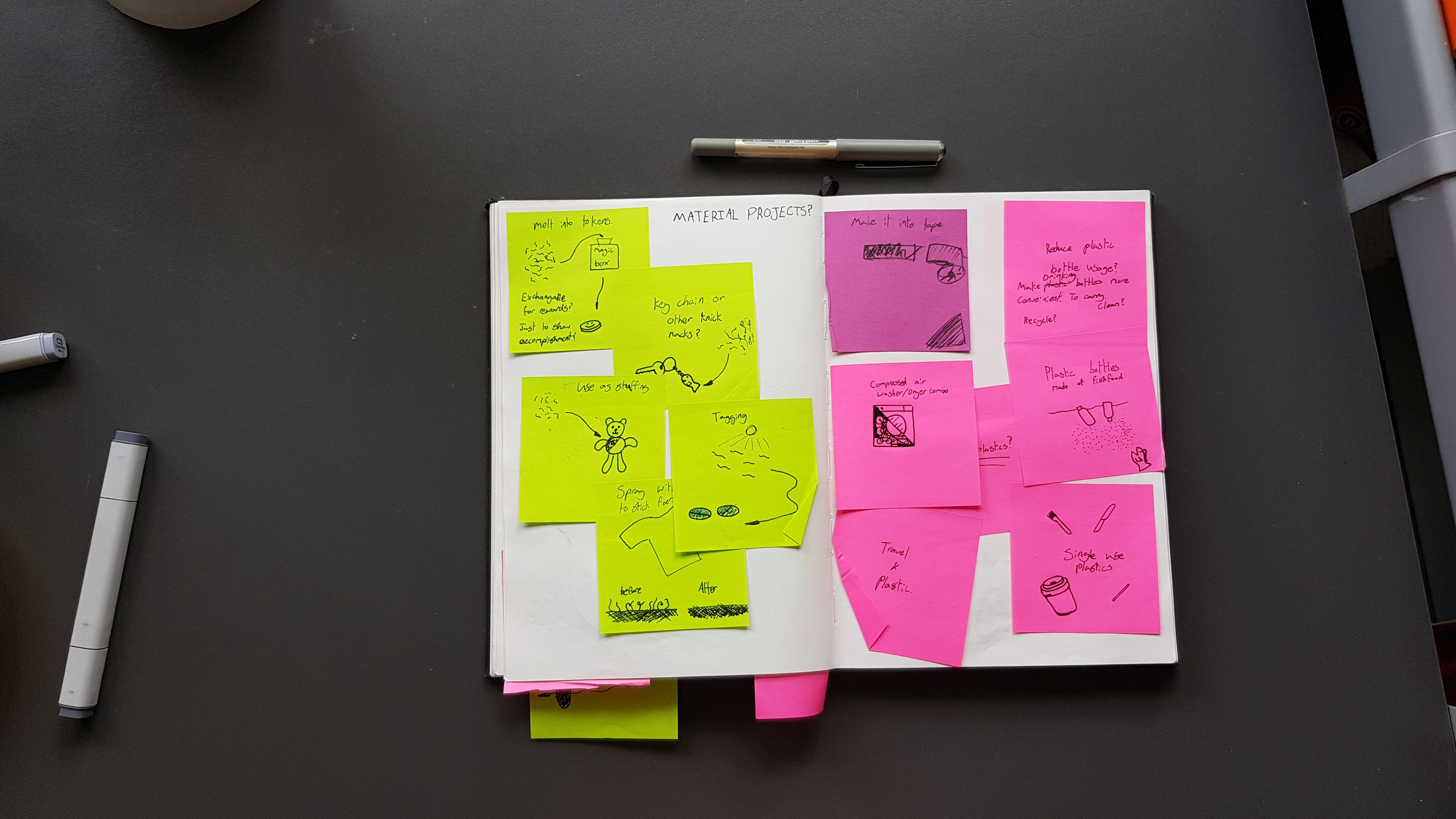

Finding a way to tackle microfibre pollution required much brainstorming

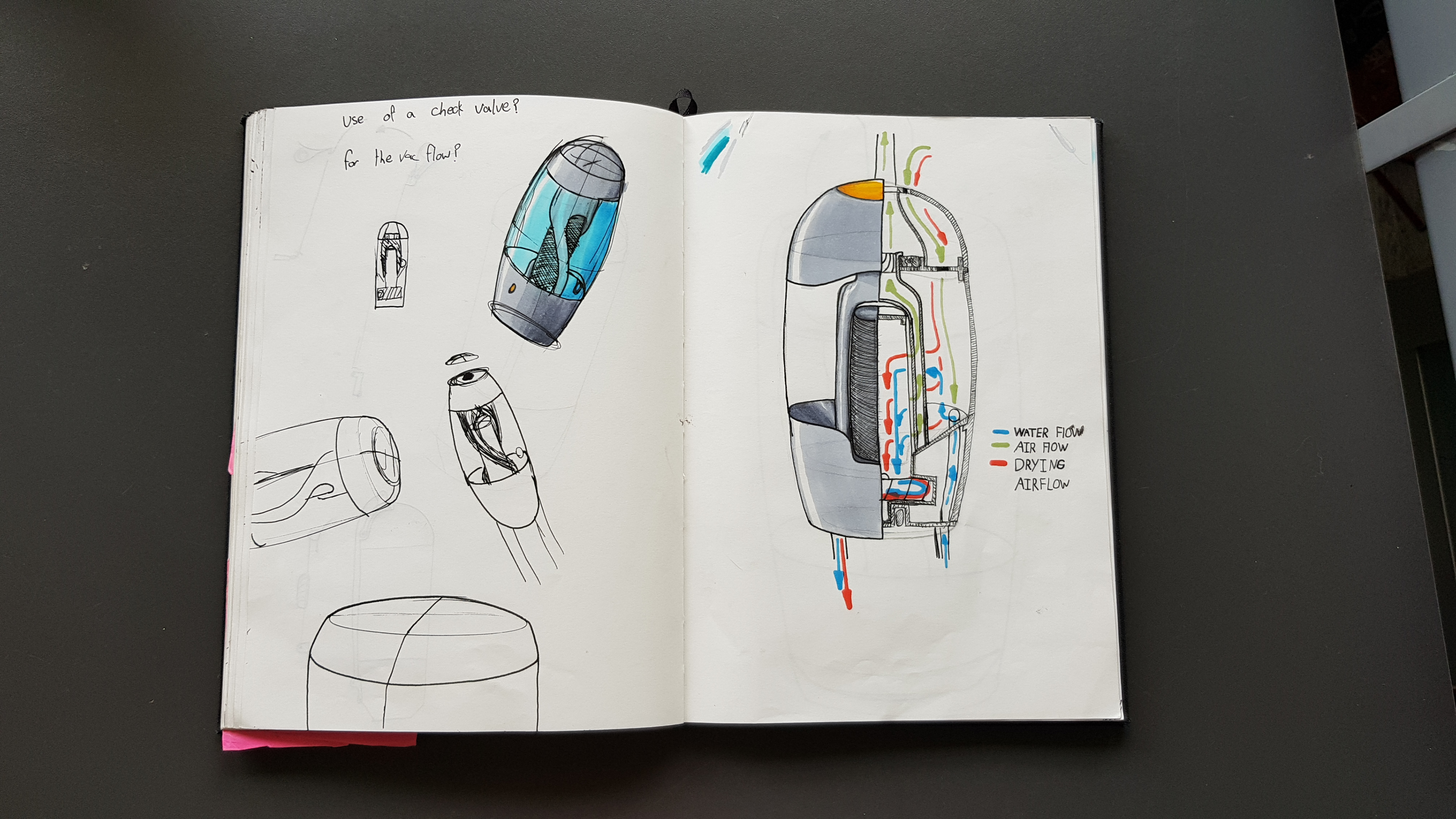

First concepts using vacuum power for cleaning

Card models were very helpful in figuring out good proportions for the product

Over time, the cleaning mechanism was developed to rotate using the force of airflow running over fan blades

Visualising potential routes for airflow

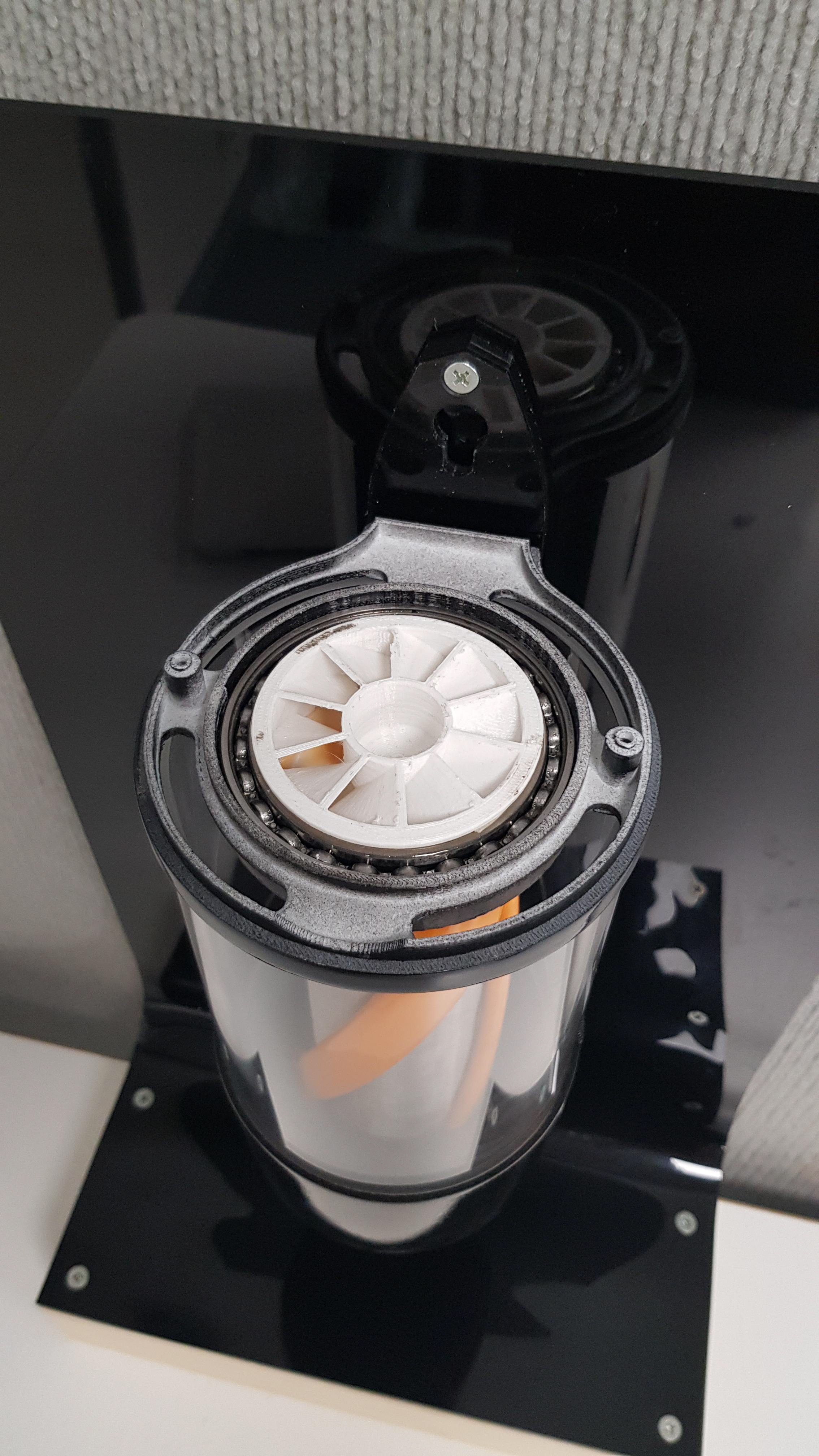

3D printed prototypes were crucial in developing the cleaning mechanism

Final concept 3D print

Creating a stand for exhibiting

Internal view of the fan blades that imparts the spin on the cleaning mechanism.

AWARDS

James Dyson Award- International Top 20 2019

The James Dyson Award is an international design award that celebrates, encourages and inspires the next generation of design engineers. Run by the James Dyson Foundation, the Eddy was among the 20 finalists chosen by a panel of Dyson engineers based in the UK and SEA who worked through a shortlist of national finalists selected from thousands of entries from the 27 participating countries and regions.

The James Dyson Award is an international design award that celebrates, encourages and inspires the next generation of design engineers. Run by the James Dyson Foundation, the Eddy was among the 20 finalists chosen by a panel of Dyson engineers based in the UK and SEA who worked through a shortlist of national finalists selected from thousands of entries from the 27 participating countries and regions.

Australian Good Design Award- Next Gen 2019

Received for my work on my thesis project- Eddy “There is clear effort, thought and consideration that has gone into this design. The Jury saw this as an intelligent and viable design solution to a significant environmental threat.”

Received for my work on my thesis project- Eddy “There is clear effort, thought and consideration that has gone into this design. The Jury saw this as an intelligent and viable design solution to a significant environmental threat.”

If you would like to see a copy of my full process journal, please contact me.